Dual output rotary speed sensor hall effect

Description

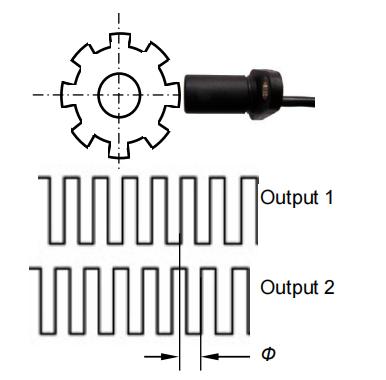

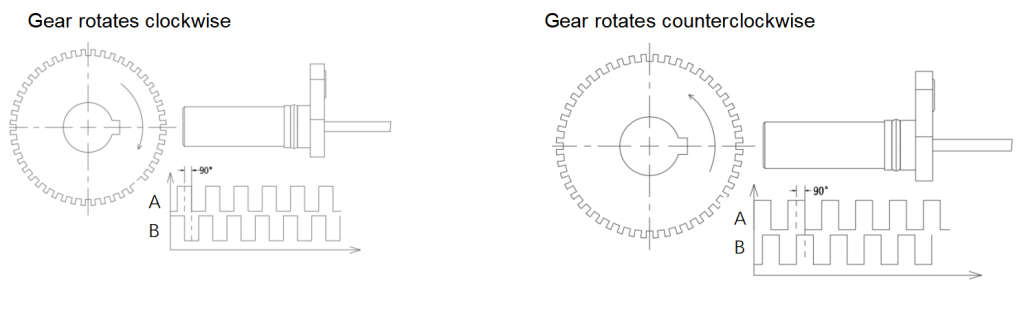

Yuli Intelligent YH-104X series speed sensors are designed for sensing target’s movement such as rotational speed, direction and position. With Hall-effect integrated circuit (IC) and a permanent magnet(samarium cobalt magnetic material) all sealed inside the rugged and probe-type package (PA66+GF30 engineering plastic/brass),the IC detects alternation of magnet’s flux density when it approaches a ferrous metal target which is usually a gear wheel composed of Fe Co Ni materials(e.g. silicon steel ) or a permanent magnet. When the gear wheel rotates, the sensor will generate two square-wave pulses (e.g. A and B) whose quantity is proportional to quantity of gear convex poles. This sensor is featured with outstanding performance of resistance to vibration and high operating temperature. With EMI radiated immunity protection built in, it can resist to great impulse of external current and voltage.

VALUE TO CUSTOMERS

- Higher durability:

Wide operating temperature range enhances higher reliability

Wide supply voltage range improve compatibility

IP69

Built in high-temperature magnet with strong stability

Electrical noise immunity protection for longer equipment uptime

- Optimized product structure, minimize service cost.

- High performance design redundancy, minimize issue of after sales service.

Features

- High sensitive signal output: sensing gear width minimum to 1mm.

- Wide operating temperature range: -50°C to 155°C (Brass)

- Easy installation, fixed position

- Environmental sealing: Moisture ingress protection rated to IP69K

- Strong electrical noise immunity, EMC EN IEC 61000-6-4:2019/EN IEC 61000-3-2:2019+A1:2021/EN 61000-6-2:2019

- Robust resistance to vibration: IEC60068-2-64-2019

- Wide working frequency range:0Hz-20KHz

- Wide supply voltage range: DC 4.5V-DC 30V

- Low power consumption current:3mA-5mA

- Standard square wave output, high resolution clearly displayed on oscilloscope.

Potential Application

- Measuring rotary speed and direction of motors

- Measuring rotary speed and direction of vehicle wheel

- Measuring displacement

- Measuring machine tool spindle speed and direction

| ELECTRICAL SPECIFICATIONS | ||||

| CHARACTERISTIC | CONDITION/COMMENT | PARAMETER | ||

| YH-104X-SC-45 | YH-104X-SC-45-33 | YH-104X-LD | ||

| Supply Voltage | DC 12V ISO 16750-2 | 4.5V-30V | ||

| Consumption current | 3mA-5mA depends on power supply | |||

| Reverse Voltage Protection | ISO 16750-2 | -30Vdc | ||

| Over Voltage Protection | ISO 16750-2 | 33V (long term);resistance to 160V for 1hour (e.g. creepage damage) | ||

| Short Circuit Protection | ISO 16750-2 | 30V | ||

| Signal Type | Two channel, phase shifted by 90° either channel, may lead or lag. | Square wave NPN(open-collector) | ||

| Duty cycle | Dependent on target geometry and sensor-to-target orientation | 50% ±10% | ||

| High Output Voltage (Voh) | Voh ≥Vcc-0.5V | |||

| Output low level | ≤0.3V | |||

| Working frequency | 0 Hz-20K Hz | |||

| Insulation Resistance | ISO 16750-2:2012 | >10 MOhm at 500 Vdc | ||

| MECHANICAL SPECIFICATIONS | |||

| CHARACTERISTIC | PARAMETER | ||

| YH-104X-SC-45 | YH-104X-SC-45-33 | YH-104X-LD | |

| Air gap | 0.5mm-2mm | 0.2mm-2mm | |

| Housing Material | PA66+GF30 | Brass | |

| O-ring Material | 70 durometer fluorocarbon, PTFE coating 17,0 mm ID x 2,0 mm CS | ||

| Fixing Inserts | Aluminum 6061 | ||

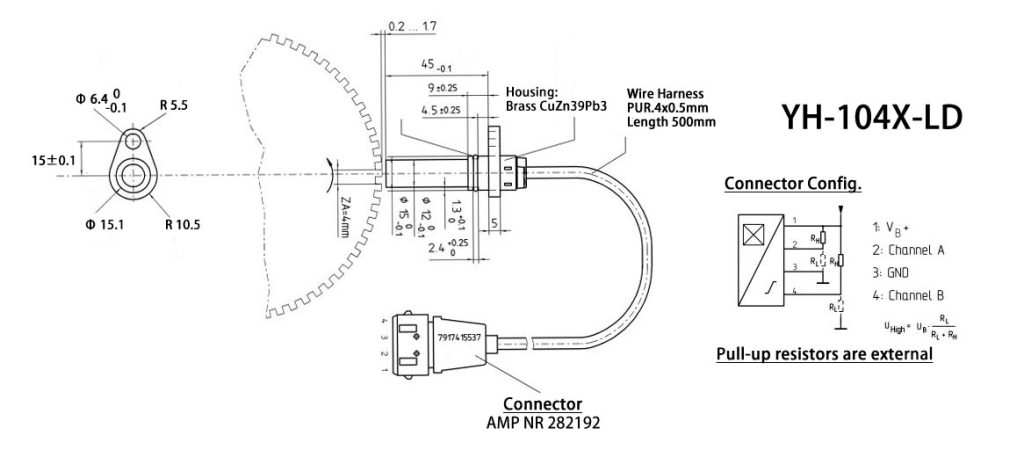

| Connector model | TE ENG-CD-282106 | AMP NR 282192 | |

| Lead length | 550±20mm | 500mm | |

| Gear Type | Spur (ferrous) | ||

| Width of tooth tip | 2mm (recommended) | 1.6mm(recommended) | 2mm (recommended) |

| Gear thickness | ≥6mm | ||

| ENVIRONMENTAL SPECIFICATIONS | ||||

| CHARACTERISTIC | CONDITION/COMMENT | PARAMETER | ||

| YH-104X-SC-45 | YH-104X-SC-45-33 | YH-104X-LD | ||

| EMC | EN IEC 61000-6-4:2019EN IEC 61000-3-2: 2019+A1:2021EN 61000-3-3:2013+A1:2019+2021EN IEC 61000-6-2:2019 | 10 kHz to 10 MHz, 60 m/V200 MHz to 2.7 GHz, 100 V/m800 kHz MHz to 1000 MHz, 3 m/V | ||

| Resistance to Vibration | IEC60068-2-64-2019 | 29.8 GRMS, 24 Hz to 2000 Hz, MIL-STD-202-214 | ||

| ESD | SAE J1113/13ISO 10605 | ±4 kV contact, ±8 kV air | ||

| Thermal shock cycle | -50°C to 145°C | 48 hours | ||

| Humidity | 95 %RH at 55°C | 10 %RH to 90 %RH at-40°C to 85°C,150 cycles, 600 hr total | ||

| Salt Fog | 5% salt solution by mass at 35°C and 93% RH for 400 hr, tested to 2000 hr with no ingress in the sensor packaging area | |||

| Flame retardant grade | UL94-V-0 | The material stops burning within 10 seconds, and the residue after burning does not appear burning sparks or flames | ||

| Oil resistance grade | ASTM D471 | No issue when immersed in vehicle oil for a long time | ||

| Operating Temperature | -50°C-130°C | -50°C-155°C | ||

| Storage Temperature | -40°C-70°C | |||

Principle

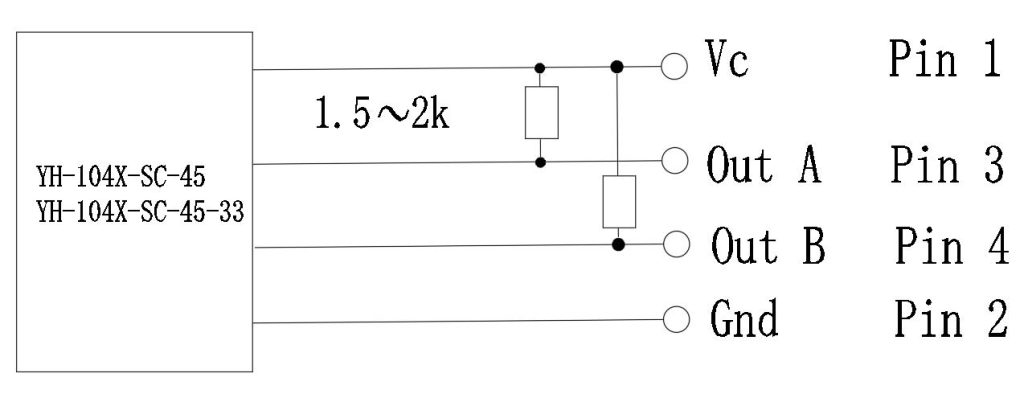

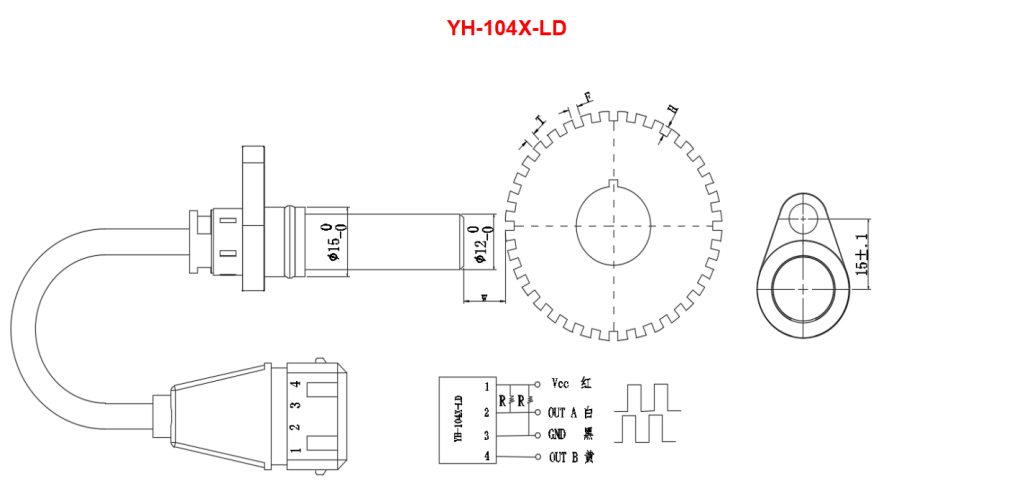

Connection

The output of the sensors is sinking current NPN (open collector). A pull-up resistor (1.5kΩ-2kΩ) should be connected to the sensor output circuit (between power supply Vcc and output). Please connect the pull-up resistors of both outputs before switching on the power supply.

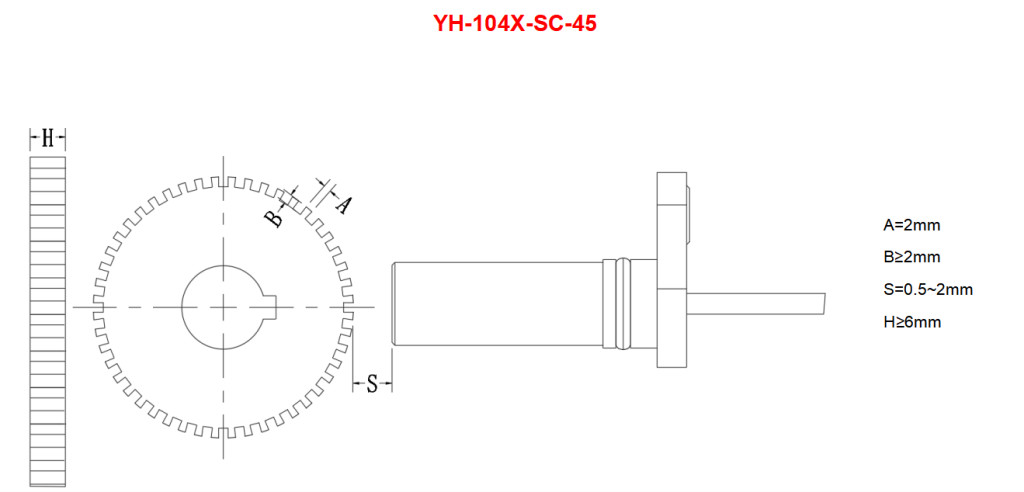

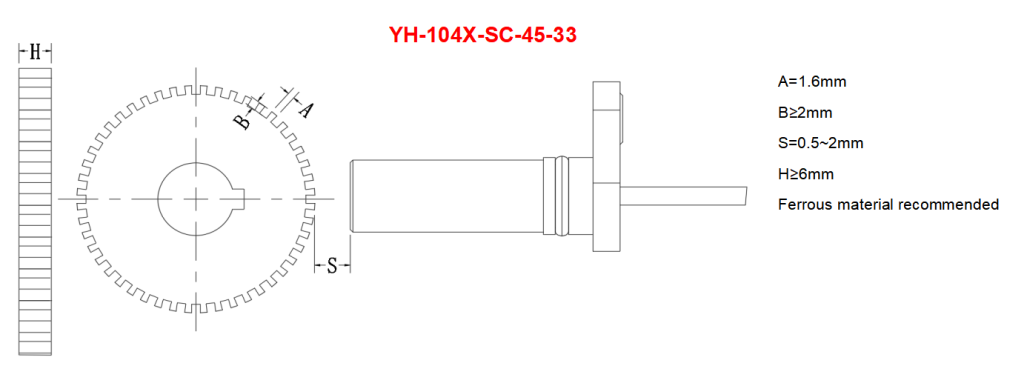

Gear Size Recommended

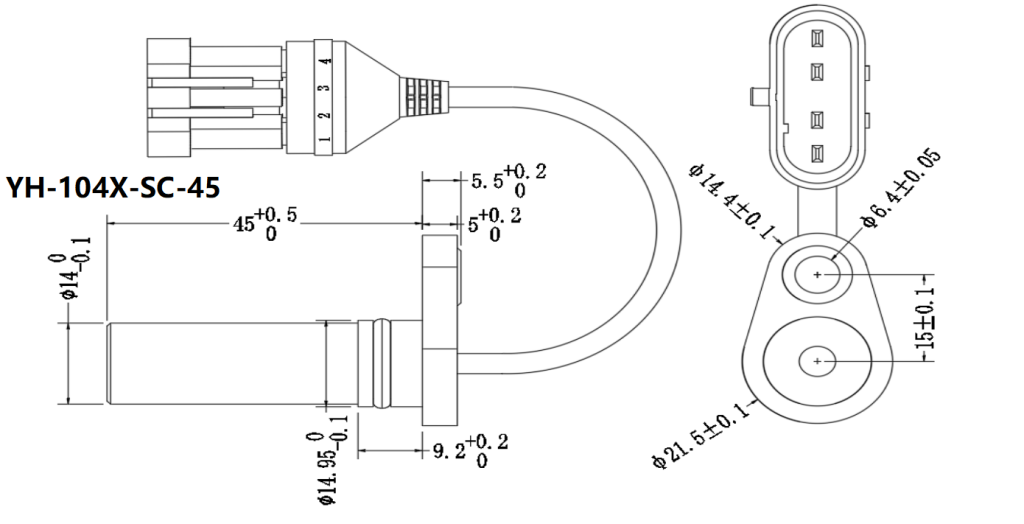

MOUNTING DIMENSIONS