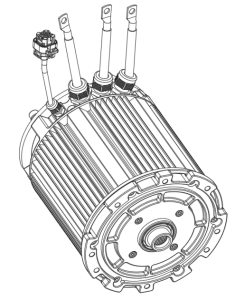

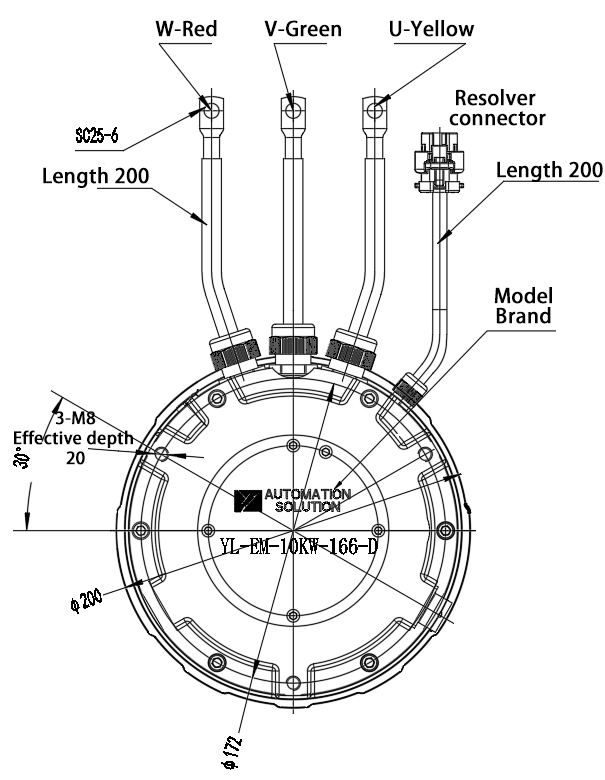

YL-EM-10KW-166-D series

Yuli YL-EM-10KW-166-D series PMSM is widely used in stable power output scenarios such as vehicles, machine tools, etc.Composed of highly reliable core components (high-temp stable permanent magnet,high performance hairpin winding,reluctance resolver and high performance bearings),this motor will provide users long term safe and reliable product experience and service.

Features

Operating Temp:-40°C~150°C

Stable service life: more than 5 years

Duty Cycle: S9

Rated Voltage:96V

Rated Speed: 2600RPM

Rated Torque: 35 N.m

Min. Zero Point Error(mechanical angle and electronic angle): ≤0.3°

Position Synchronized Performance:≥98%

Cooling method: Natural air

High Power with small dimension

Low heat generation and high energy efficiency

Parameters

| Item | Name | Spec. | Item | Name | Spec. |

| 1 | Model# | YL-EM-10KW-166-D | 9 | Rated Power | 10KW |

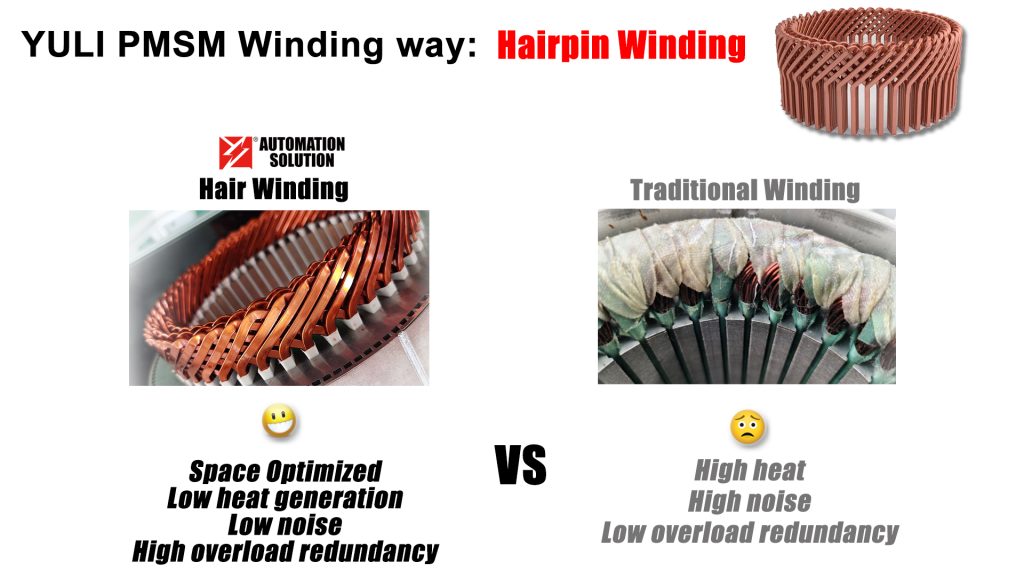

| 2 | Type | Three-phase PMSM (hairpin winding) | 10 | Peak Power | 22KW |

| 3 | Pole pairs | 4 | 11 | Duty Cycle | S9 |

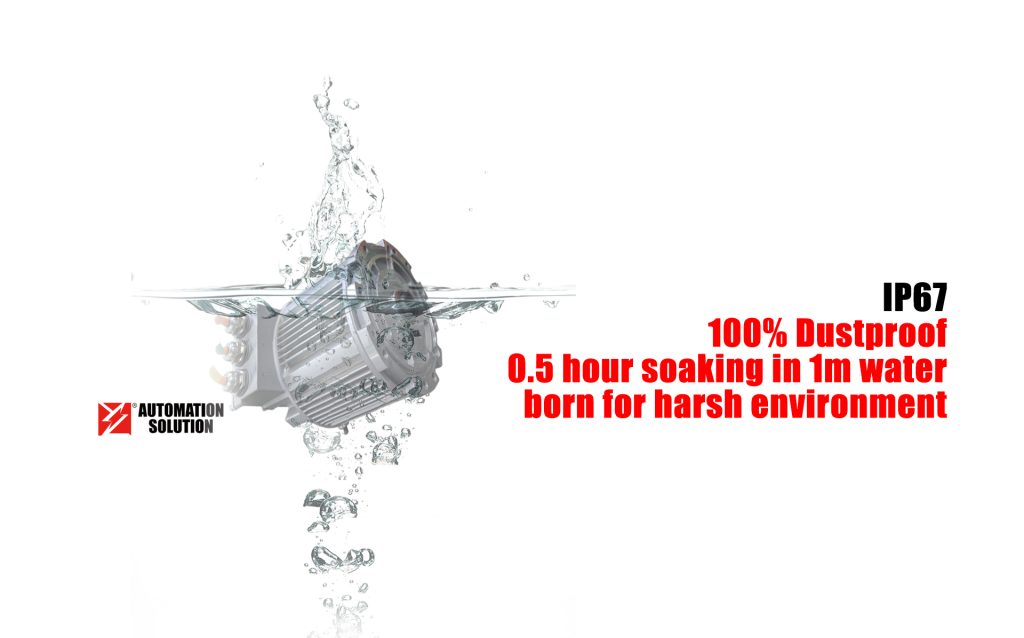

| 4 | Rated Voltage | DC 96V | 12 | Protection level | IP67 |

| 5 | Rated Speed | 2600RPM | 13 | Operation Temp | -40ºC~150ºC |

| 6 | Peak Speed | 4000RPM | 14 | Temp Sensor | NTC 10K 3435@25º |

| 7 | Rated Torque | 35 N.m | 15 | Position Encoder | 4 pole pair reluctance resolver |

| 8 | Peak Torque | 90 N.m | 16 | Min. Zero Point Error | mechanical angle and electronic angle ≤0.3º |

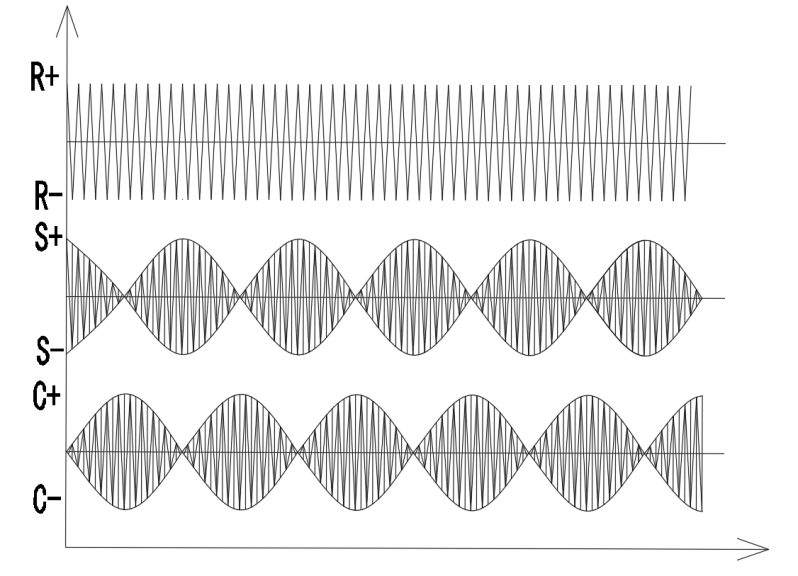

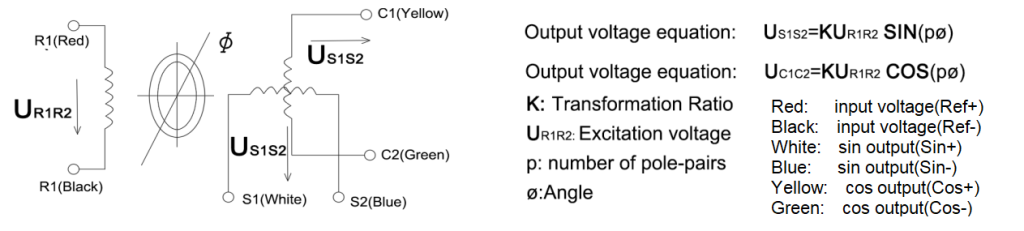

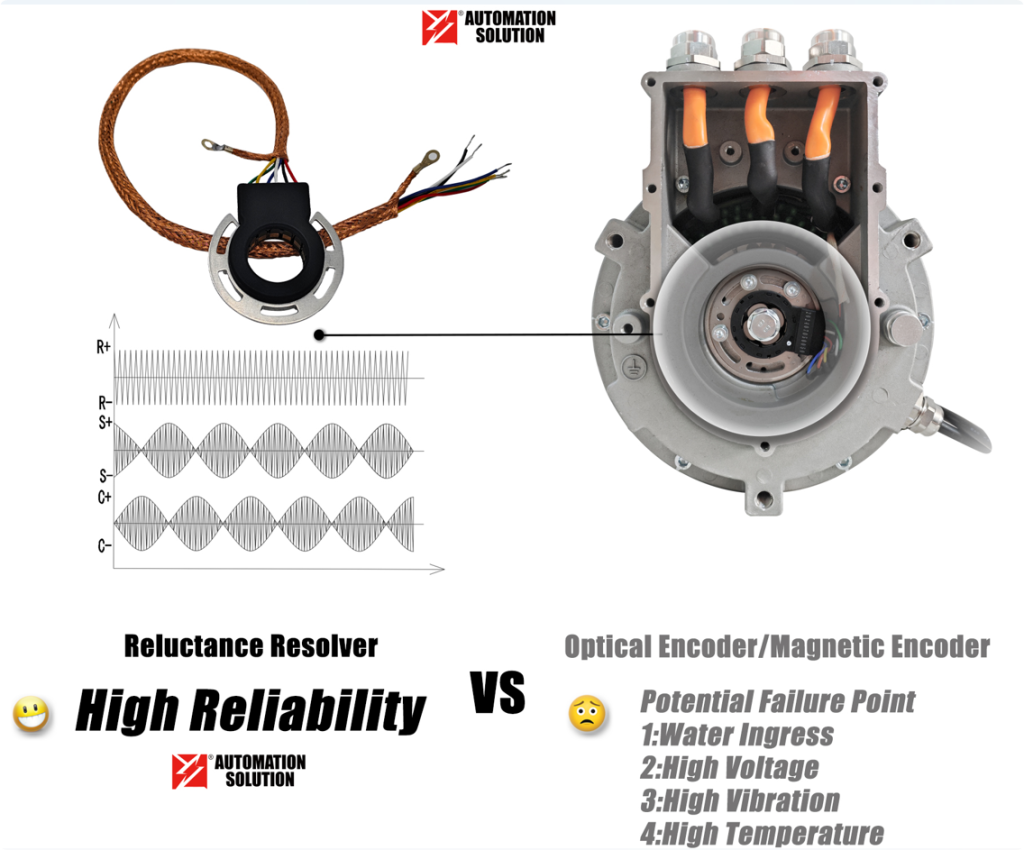

Position Encoder

| Name | Specification |

| Pole Pairs | 4 |

| Power Supply | 10K HZ AC7V rms |

| Transformer Ratio | 0.286±10%static 0.286±2% dynamic |

| Electrical error | ≤15′ |

| Input impedance | 110±10Ω |

| Min. Zero Point Error | ≤0.3º |

| Recommended decoding chip | AD2S1210WDSTZRL7 (12bit,4096) |

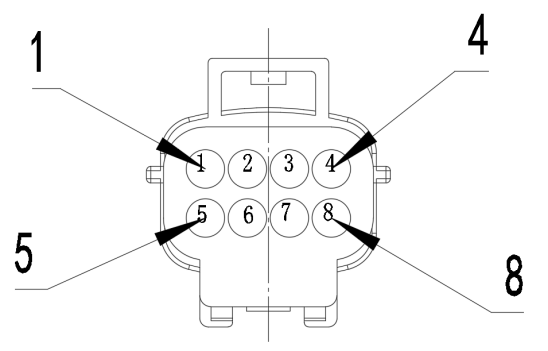

Low-voltage connector model comparison table

| # | Name | Spec. |

| 1 | Motor connector | DJ70816Y-1.8-11 |

| 2 | Controller connector | DJ70816Y-1.8-21 |

Low-voltage connector Electrical Parameters

| DJ70816Y-1.8-11 PIN definition | |||

| Port | Color | Aperture(mm) | Definition |

| 1 | Brown | 7.5 | NTC – |

| 2 | White | 7.5 | Sin + |

| 3 | Yellow | 7.5 | Cos + |

| 4 | Red | 7.5 | R1 + |

| 5 | Grey | 7.5 | NTC + |

| 6 | Blue | 7.5 | Sin – |

| 7 | Green | 7.5 | Cos – |

| 8 | Black | 7.5 | R1 – |

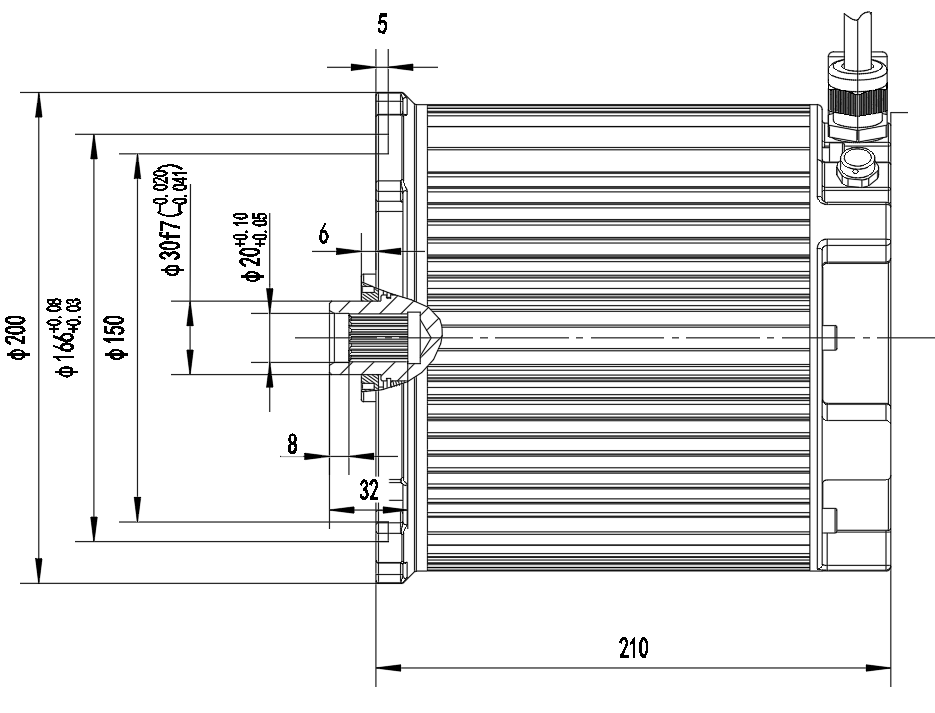

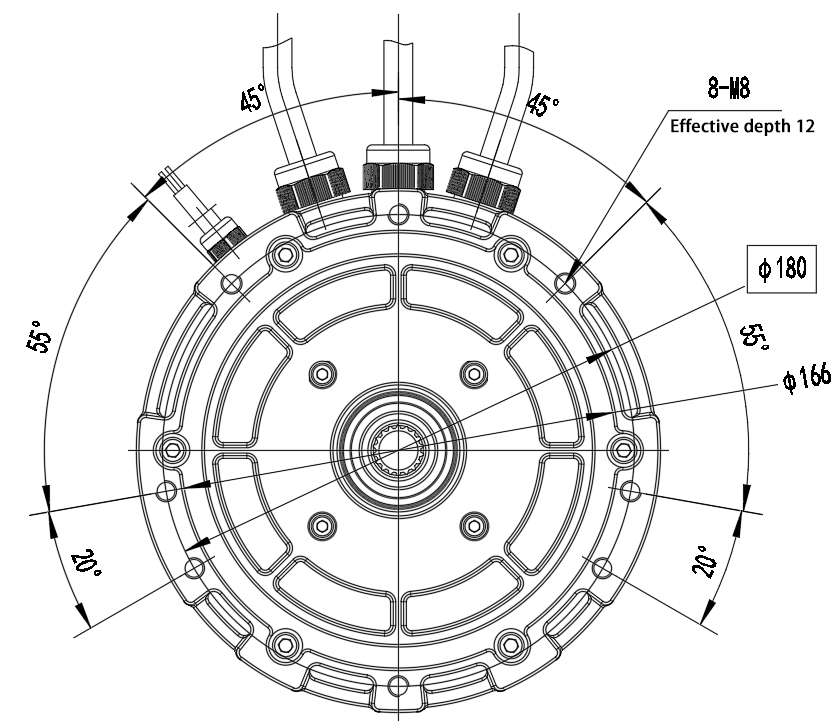

Structure

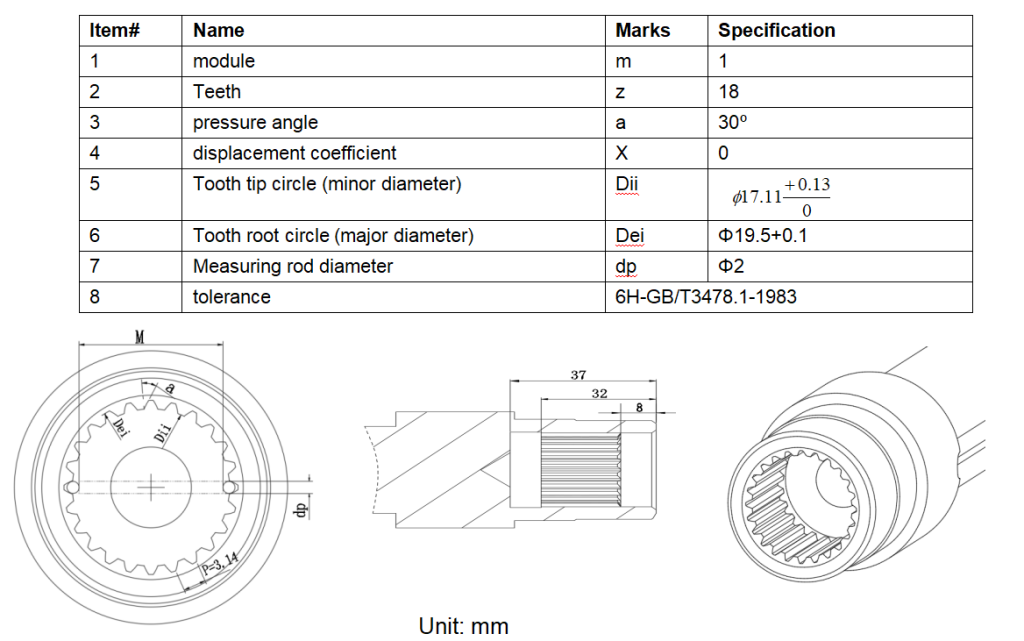

Involute Internal spline parameters

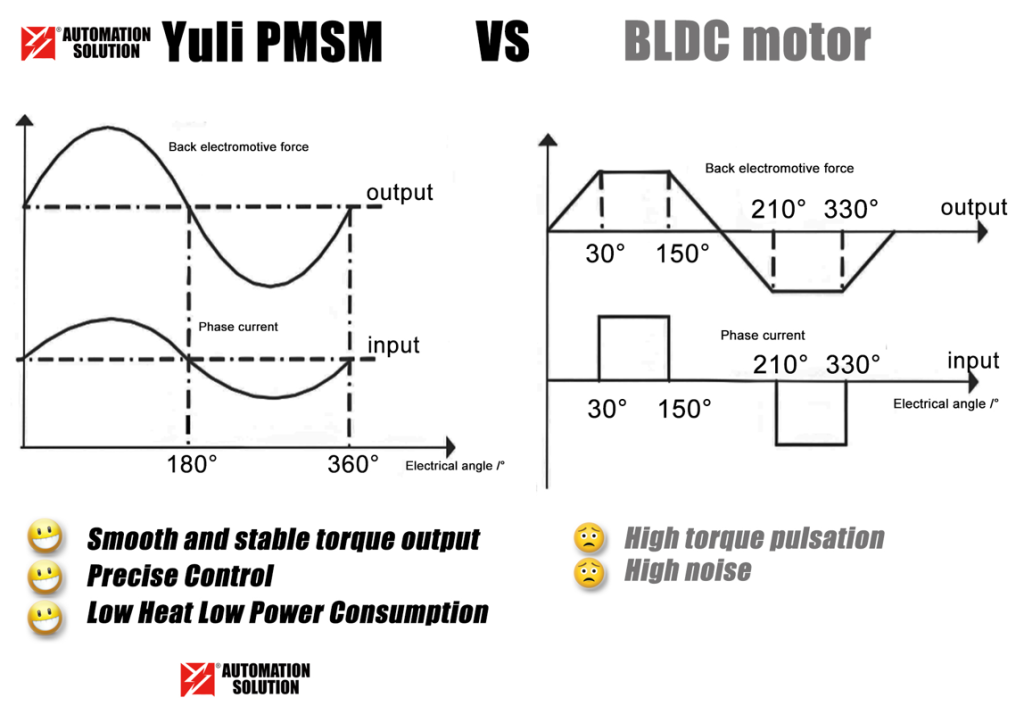

Real Permanent Magnet SYNCHRONOUS Motor

Is your motor a real Synchronous Motor?

those with incremental encoders built in are actually NOT real Synchronous Motor!

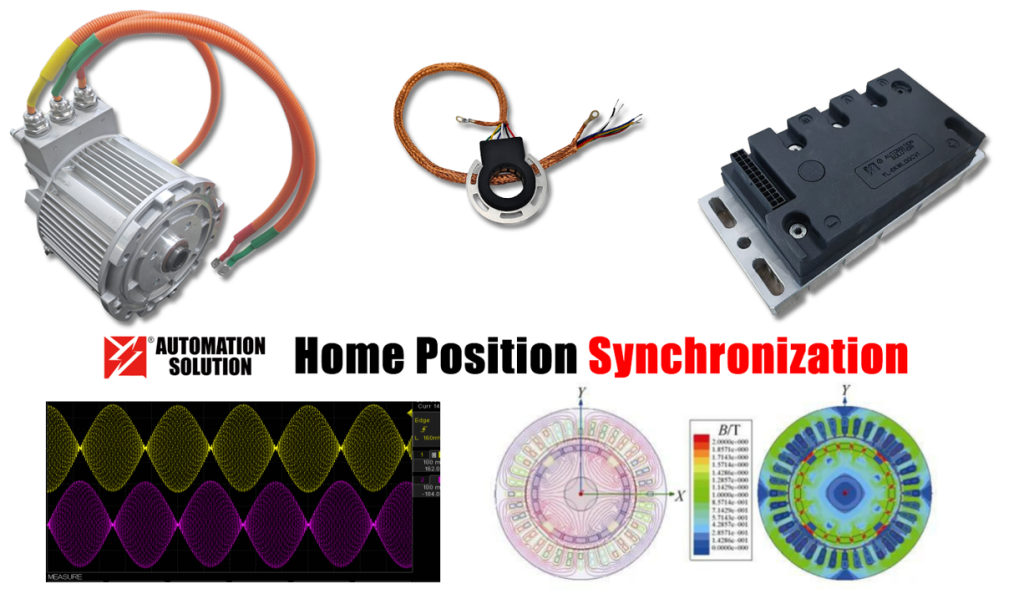

We re-define PM Synchronous Motor during our motor production,

We synchronize home position of Encoder,home position of motor and home position of Controller,

We also synchronize performance of material,home position and output sine wave.

Minimum Zero Point Error (mechanical angle and electronic angle): ≤0.3°

Position Synchronized Performance:≥98%

Reluctance Resolver Built in motor as absolute encoder

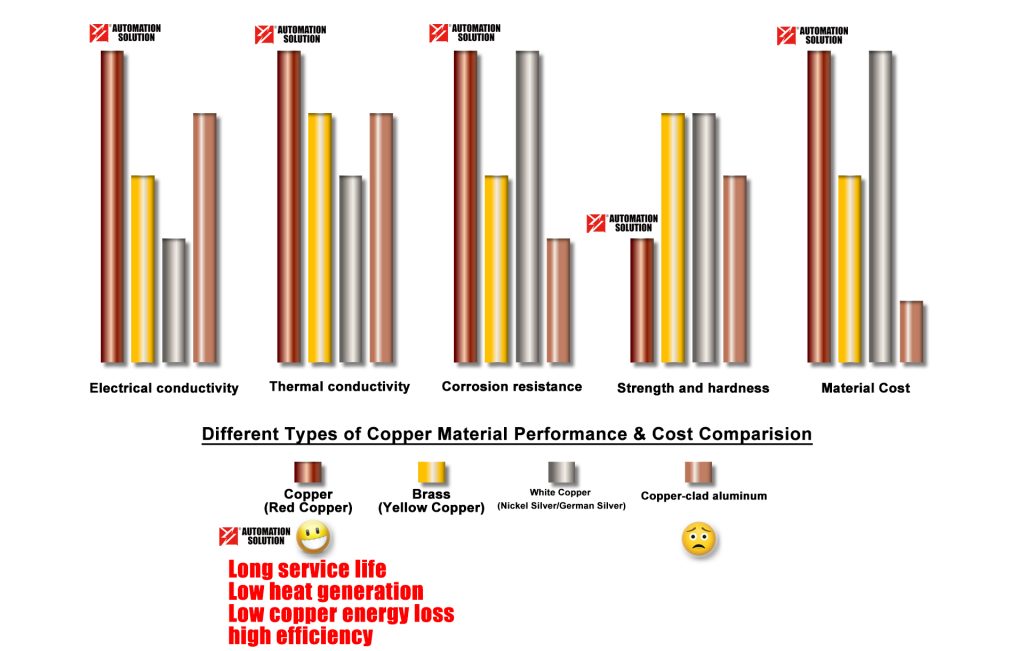

Yuli PMSM use High Performance Material

YULI PMSM Winding material:100% red copper

Yuli PMSM Hairpin winding

Yuli PMSM Hairpin winding IP67

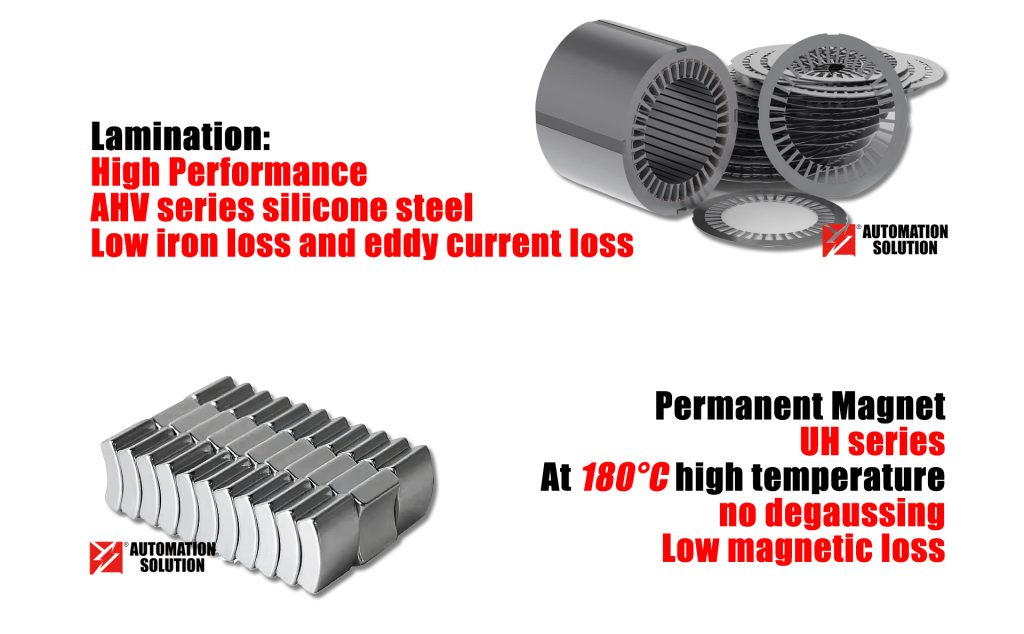

Lamination: AHV series silicone steel

Permanent Magnet: UH series, 180°C no degausing

SKF high performance bearings