What is real permanent magnet synchronous motor?

4KW-10KW Permanent Magnet Synchronous Motor(PMSM) nowdays are widely applicated to small EVs ,electric motorcyles,e-bikes,electric tricycle, Automatic Guided Vehicles(AGV),electric All Terrain Vehicles(ATV) and electrified marines.

Motorcycle owner or bike consumers may just know their E-bikes equipped with a 4KW electric motor which may be called by supplier as PMSM,but they did not really understand how is the performance of this motor,and is it a real PMSM?answers may be NO.

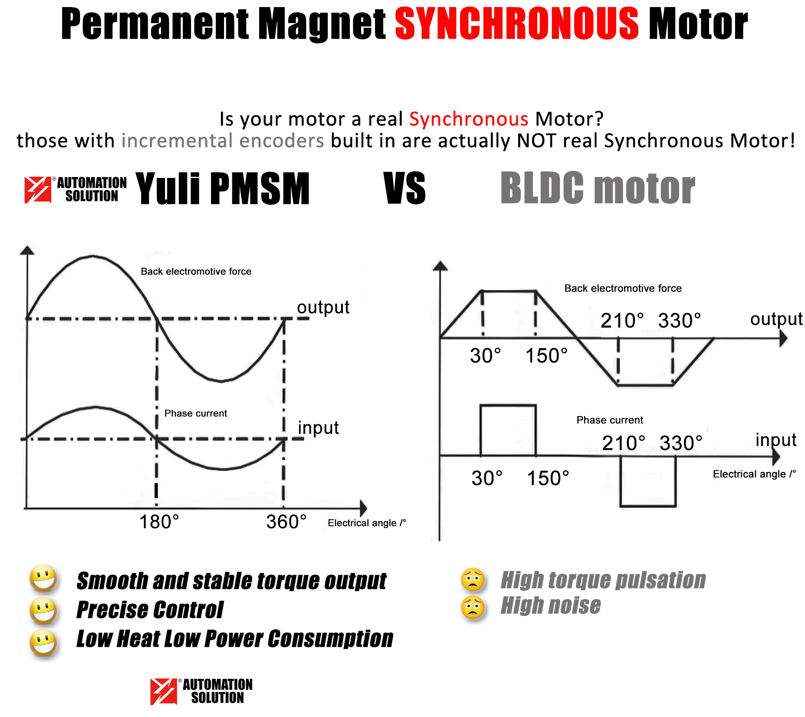

In fact, our tech team believe that those with incremental encoders built-in are NOT real PMSM,especially for a synchronous motor!Guangzhou Yuli design and manufacture real PMSM.

Why is synchronization important for a PMSM?People may not tell out the differences between PMSM and BLDC motors in daily common operation,but for a vehicle, there will be always safety risk when BLDC motors mounted.Because of incremental encoders, signals can not be continuous, smooth and stable ,therefore BLDC motors will have high torque pulsation and high noise, which leads to unreliability to motor control ,higher heat generation,lower power efficiency and shorter service life.Only high Synchronization will be the key to solve those issues.

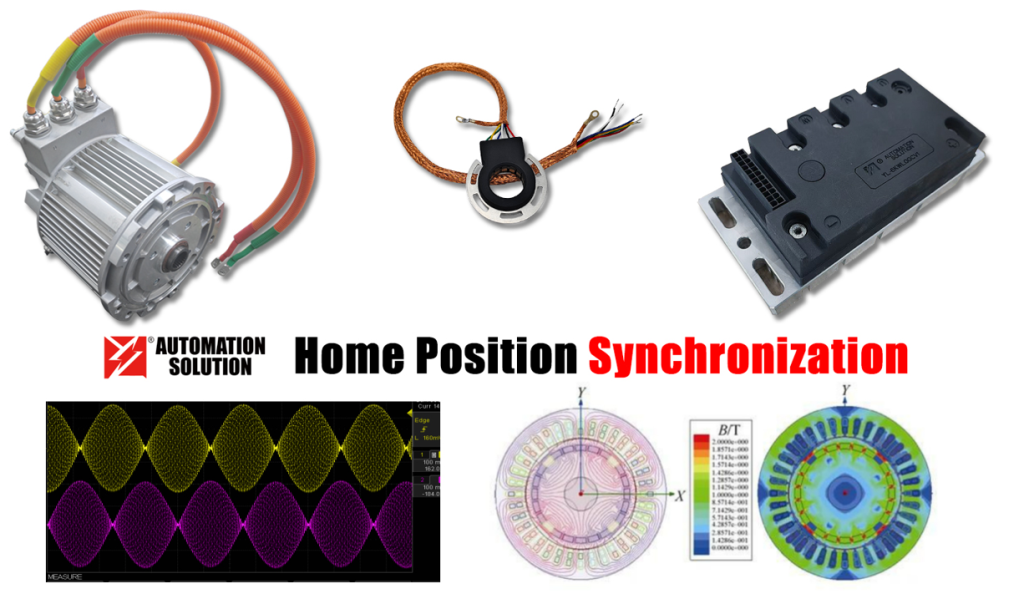

We re-define PM Synchronous Motor during our motor production,We synchronize home position of Encoder,home position of motor and home position of Controller,We also synchronize performance of material,home position and output sine wave which usually is overlooked by motor manufacturer.Our motor Minimum Zero Point Error (mechanical angle and electronic angle): ≤0.3°,Position Synchronized Performance:≥98%,which are great achievement for motor with 4KW-10KW powers.

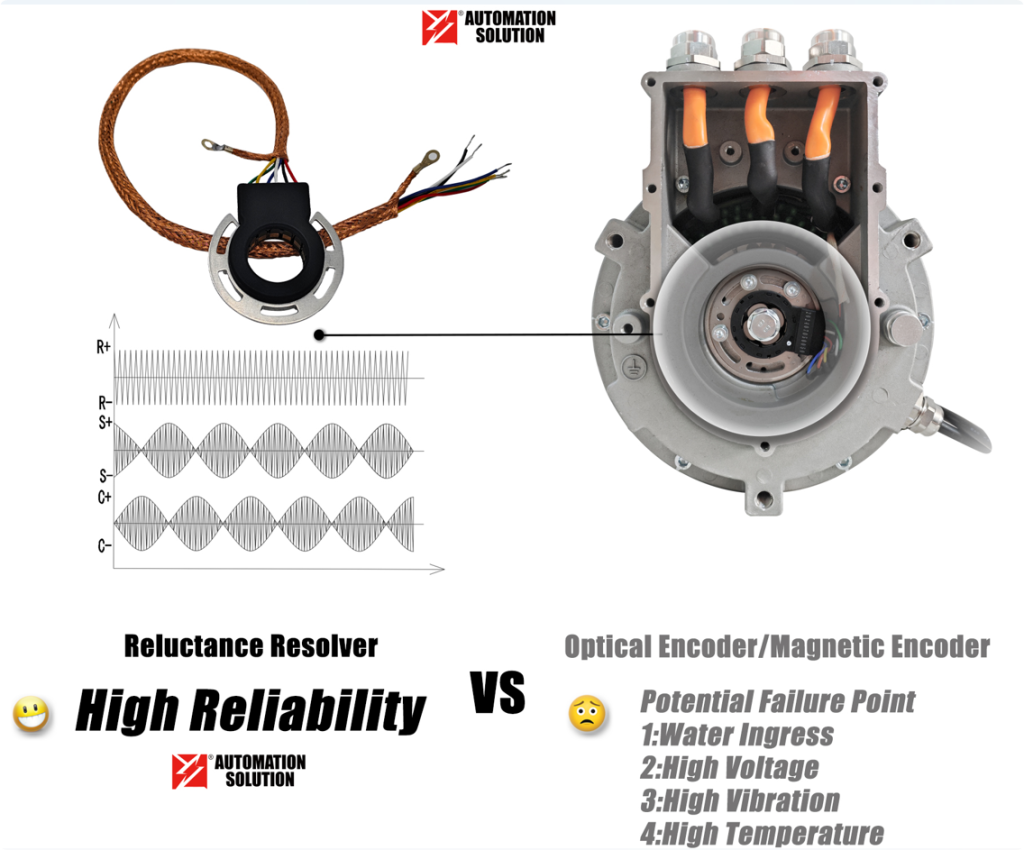

How significant is a high reliable encoder for a motor?As core component in the PMSM,resolver as absolute encoder will solve those failure points that optical encoders have ,e.g: water ingress,high voltage load,high virbration and high temperture.With YULI motor synchronization system, All PMSM motors manufactured by YULI are equipped with high reliable resolver as encoders,which can be controlled precisely by YULI’s motor drives.

What is advantages of YULI PMSM?

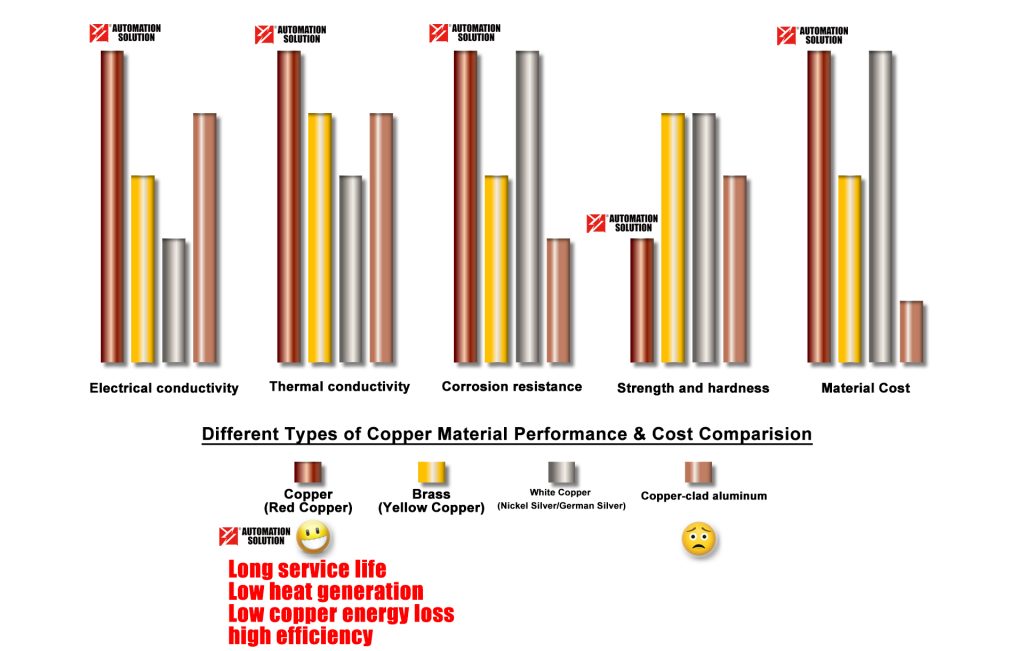

1.100% red copper as winding material,not brass, not copper-clad aluminum,long service life, low heat generation, low energy loss and high efficiency.

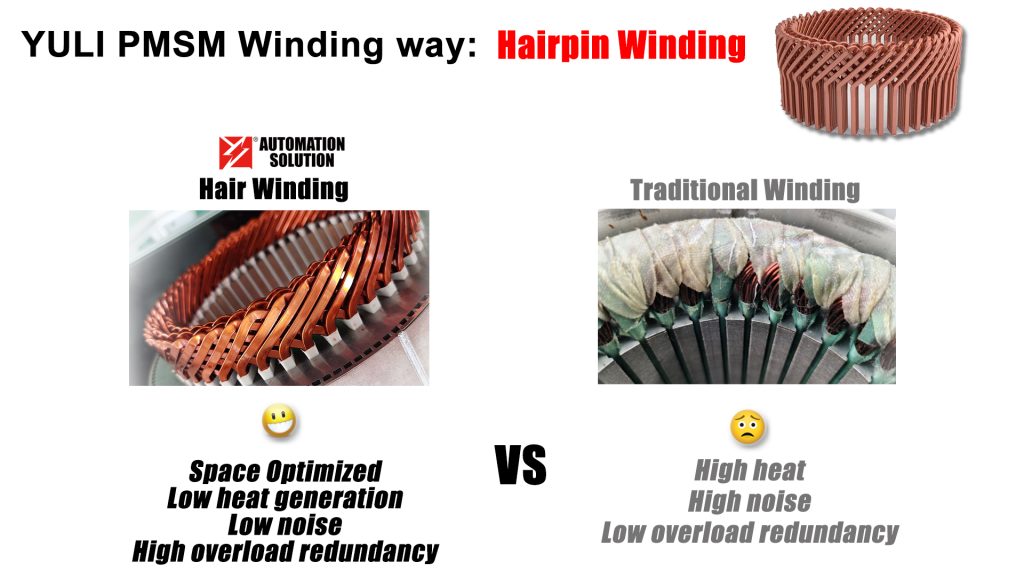

2.Hairpin Winding: Space Optimized,low heat generation ,low noise and high overload redundancy.

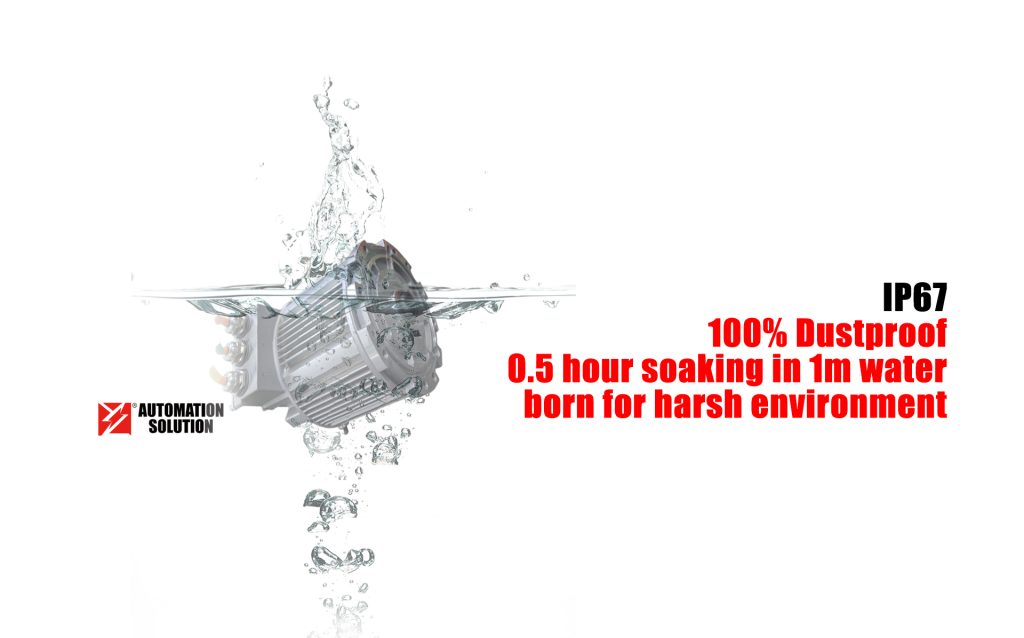

3.IP67, deisigned for harsh environment

4.High Performance and high quality material:

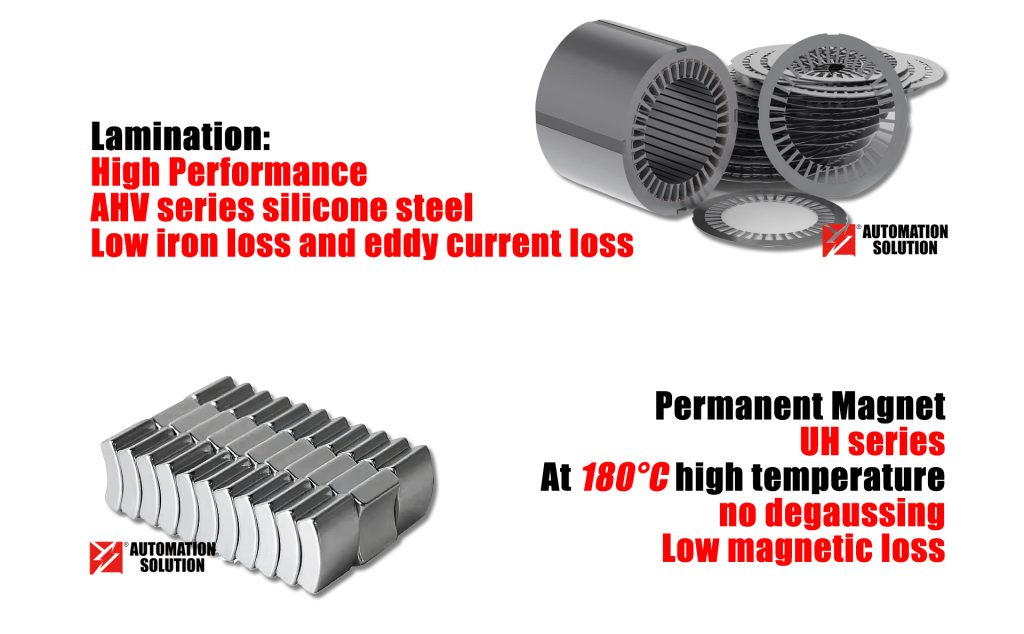

Lamination:AHV series silicone steel,low iron loss and eddy current loss

Magnet:UH series,high temperature 180 °C no degaussing

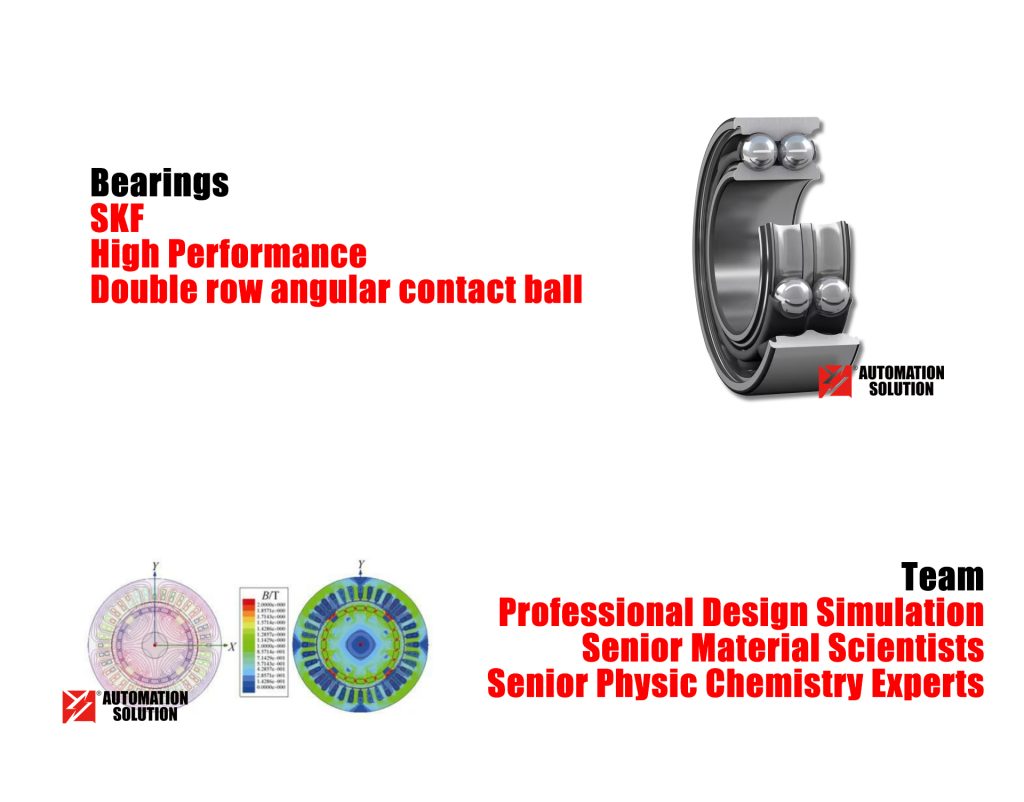

5. High Performance Bearings: SKF

6.Experienced tech support team

With 16 years tech accumulation,Guangzhou Yuli released a series of high performance 4KW-10KW 72V-96V real PMSM, filling a market gap of high end PMSM with such power, providing more options for those who want to electrify their machines.

More detail: https://www.yuli-auto.com/motor/

Commercial Cooperation